Converting Patterns

Identifying the problem is half the battle

If you want to knit a design but can't quite come to terms with the, you can quite easily convert the pattern. First of all, check where the problem is.

The most important thing before starting to knit is to check the gauge. If you want to knit a pullover using the original yarn in one of the sizes given, then compare your gauge swatch check tot eh gauge given in the instructions. If these two do not correspond, then knit another gauge swatch and adjust your needle size.

If you want to change the size, the stitch pattern or the yarn you‘ll have to do some prep work in order to ensure the result is perfect and fits.

The right size

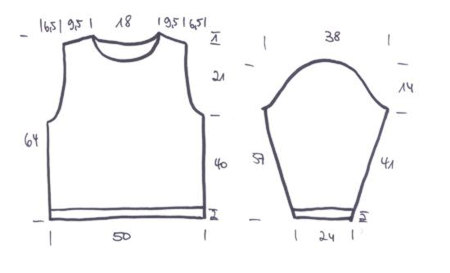

You are well advised to compare the measurements of the schematic of the chosen item with your favourite one in your own wardrobe.

If you prefer to make it longer, shorter, wider or tighter, it’s best to draw a new schematic with your desired measurements – preferably on a scale of 1:1. So when placing your work onto the new schematic you can always check measurements and make adjustments on the go.

Rule of three

Now all you have to do is convert the measurements into stitches and rows. That's where the rule of three comes in more than handy. Your gauge swatch tells you how many stitches and rows you need per 10 cm.

Gauge swatch: 16 stitches and 24 rows = 10 x 10 cm

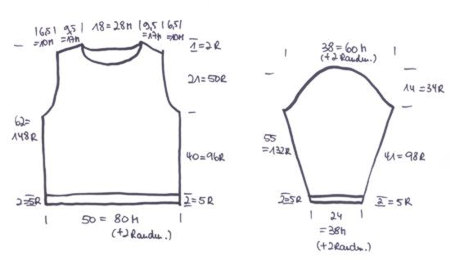

Example cut diagram:

You‘ll need 16 stitches per 10 cm = 1.6 stitches per 1 cm, and five times as much for 50 cm (width of front and back), so 80 stitches per panel.

Don't forget the selvedge stitches! In length you‘ll need 24 rows per 10 cm = 2.4 stitches per 1 cm, and four times as much for 40 cm (length measured from hem to armhole on the front and back panel), therefore 96 rows.

The conversion formula is: (cm x gauge swatch) divided by 10 = eg. 50*16/10 = 80 or 40*24/10 = 96.

Determine the benchmark data for your garment by converting all measurements width-wise into stitches and length-wise into rows.

If your calculations don't result in a whole figure, round up or down. One stitch more or less won’t make a big difference.

Shaping sleeves, armholes and necklines

In the example above all increases in width have to happen within 7 cm per side (11 stitches per side + 2 selvedge stitches) and in length within 41 cm (98 rows) = 38 cm width after increasing minus 24 cm before increasing = 14 cm.

Now divide the number of rows by the number of stitches = 8,9, let’s round it down to 8. You’ll have to increase 11x 1 stitch on both sides on every 8th row. Don’t increase on the last few rows before the top shaping. When the division results in an odd stitch count, let’s say 7, increase on every 6th and 8th round instead.

For the top shaping, the armhole and neckline it’s best to place your knitted panel on top of the 1:1 schematic and start decreasing on all edges as necessary. Often the differences to the original pattern aren’t that big, so don’t hesitate refering back to the pattern as a guideline.

Repeat patterns, colorwork motifs and area division

If you are knitting repeating patterns (ribbing, cables, lace, etc.) take the number of stitches and rows per repeat into consideration.

Sometimes the only solution is a compromise between measurements and stitch pattern. Either the measurements or the stitch pattern has to be adapted. It’s best to stick to the original instructions. Compare various sizes from the original pattern as reference. Knitted motifs or repeating areas should be placed on top of your drawn schematic. Calculate the exact position using the rule of three or place your work directly onto the schematic and use that as guide.

One more tip

It can’t be stressed enough on how important a gauge swatch is! Always knit a gauge sample before starting your actual work!

Everything else depends on your gauge, including your success! But knitting should be fun, so don't turn it into a PhD thesis! A little improvisation is always allowed ;)